Shipping containers come in a variety of shapes and sizes, from standard 20 and 40ft units to less commonly used 8 and 10ft containers. For the most part, these containers fit plenty of items comfortably for transit. But what happens when your items or equipment don’t quite fit?

That’s when you’re dealing with out-of-gauge cargo — oversized loads that require a different approach. This means you’ll need to reevaluate how you ship your cargo and the type of container you use. Don’t worry, we cover everything you need to know about OOG cargo and containers, so you can prepare your load appropriately.

What does Out of Gauge (OOG) cargo mean?

Out of Gauge (OOG) cargo refers to shipments that exceed the standard dimensions or weight limits of typical shipping containers or transport vehicles. OOG is a broad term, but generally applies to cargo that exceeds the dimensions of a 40ft container. OOG shipments are typically oversized or overweight, which means they need special handling, equipment, and planning to ensure safe and efficient transportation.

The term ‘out of gauge’ is commonly used in the shipping and logistics industry to notify handlers that additional care, attention, and planning are required. This could mean bringing extra staff in, hiring specialist equipment, or creating additional space for the cargo. OOG cargo could include any item that doesn’t fit within standard shipping containers, from large machinery and industrial equipment to construction materials.

If you’re involved in international trade or transportation or large goods, understanding OOG cargo is essential. As expected, unusually sized cargo will impact costs, timelines, and logistics strategies, so it’s important to get it right.

Types of OOG cargo

When shipping cargo, many different products and machinery will fall into the out-of-gauge category. The most common types of cargo that are classed as out of gauge include:

- Military transport – armed personnel carriers or missile launch systems

- Subsea extraction equipment – subsea manifolds or remotely operated vehicles

- Oversized steel reels – huge cable drums or reels for offshore power lines

- Industrial equipment and heavy machinery – hydraulic presses or tunnel-boring machines

- Construction materials and components – prefabricated bridge sections or concrete beams

- Wind turbine blades and components – 80-metre blades

- Oil and gas refinery equipment – distillation columns or pressure vessels

- Agricultural machinery – combine harvesters or large tractors

- Large vehicles or specialised transport – mining dump trucks or airport snowplows

Transporting OOG cargo

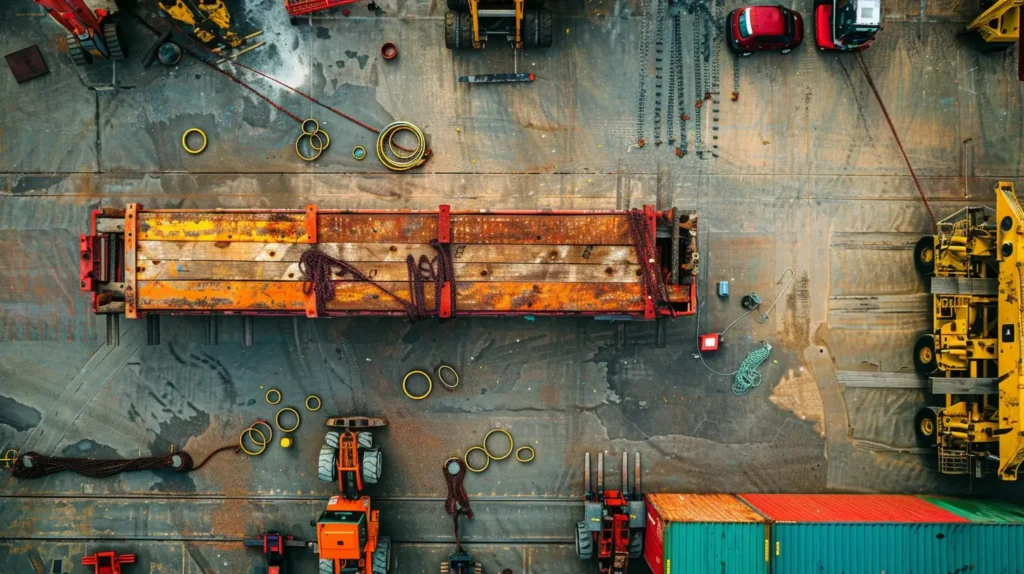

Since OOG cargo cannot be transported using standard-sized shipping containers, specialist OOG containers are required, alongside careful planning for safe container loading and unloading. Out of gauge cargo utilises several main transport types: roll-on/roll-off vessels, open top containers, flat rack containers, flatbed containers, full vessel charters, and aircraft.

Roll-on/roll-off vessels

If cargo is on wheels or can be placed on a platform vehicle, roll-on/roll-off (RoRo) vessels are a great solution. These vessels have large open decks and ramps for loading and unloading, allowing cargo to be driven onto multiple decks or directly into the ship’s hold.

The ease of roll-on/roll-off vessels means the use of cranes is unnecessary in many cases, streamlining the loading and unloading process. This functionality makes RoRo vessels a flexible and cost-efficient option. Security is factored in too, with anchoring systems available for securing heavy cargo during transit.

Flat rack containers

Flat rack containers are frequently used for transporting OOG cargo. These containers have flat platforms with fixed or collapsible end walls that allow for easy loading and unloading of large or awkward cargo. Flat racks are commonly available in 20ft and 40ft lengths and do not have side walls.

Loading cargo onto flat rack containers is usually performed with forklifts to the sides, or from above with cranes. With no roof, these containers are ideal for abnormally-shaped items like machines, boats, and long structures.

As a guide:

- A 20ft flat rack measures 20’ x 8’ x 8’5” and carries around 22 tonnes

- A 40ft rack measures 40’ x 8’ x 8’6” and carries around 25 tonnes

Another key feature of flat rack containers is the ability to join them for super oversized cargo, such as heavy machinery or prefabricated structures. Plus, empty flat racks can be stacked for efficient storage, which sometimes minimises the costs involved.

Open top containers

Open top containers do not have a fixed steel roof, allowing for top loading and unloading using cranes or other lifting equipment. Like other container types, they are available in 20ft and 40ft lengths, but custom options may also be sourced.

These containers have a removable roof, which is often replaced with a tilt cover or tarpaulin to protect cargo during transit. They are a great solution for tall cargo such as cranes or farm machinery, which can be easily secured with lashing bars or tie-down straps.

Dimensions and weight capacity for these containers vary among manufacturers and series, but typically, a 20ft container can carry 26 tonnes and a 40ft container can carry 28 tonnes.

Flatbeds

Flatbeds can also be used to transport out of gauge cargo. Typically, a 20ft flatbed has a payload of 31-34 tonnes, while a 40ft flatbed can accommodate 39-45 tonnes. Like most containers, the exact capacity will differ depending on the manufacturer, shipping line, and local regulations. Flatbeds can also be stacked for storage or transport when empty.

Full vessel charters

Full vessel charters are a cost-effective solution for transporting large volumes of OOG cargo. With dedicated handling, full vessel charters are typically used for massive cargo loads.

Using this option means dedicated vessel space, optimising efficiency, and potentially reducing the overall shipping costs when compared to other methods like part-cargo shipments. Although this will depend on how much cargo you intend to ship.

As a more unique solution, a full vessel charter is usually the best option when the volume and dimensions of the OOG cargo justify the cost of chartering an entire vessel.

Aircrafts

Aircraft provide rapid transport for urgent, appropriately-sized cargo, but at a high cost. Out of gauge cargo that needs to be moved by air is typically transported in specialised aircraft like the Antonov An-124 or Boeing 747-8F. This is because these aircraft benefit from large cargo doors and increased payload capacity.

Like some of the other methods, aircraft can accommodate cargo such as machinery, aircraft parts, and other oversized items. In some cases, chartered flights or priority transport may be necessary for urgent OOG shipments, even if the load would fit into a more commonly used mode of transport.

Not dealing with OOG cargo?

While OOG cargo requires special handling, permits and planning, most standard containers follow a far more straightforward process using common equipment and routes.

Find out how regular shipping containers are transported and what makes the process so much easier in our detailed guide.

Read guideHandling and shipping out of gauge cargo

Preparation is key when it comes to shipping OOG cargo. Like shipping any goods, you need to ensure they are appropriately prepared so they are handled and transported safely and securely.

Pre-shipment planning

There is plenty of planning to do before a shipment, and getting it right is crucial. With OOG cargo, certain plans and allowances need to be made for sufficient clearance on roads and under structures. This will prevent damage to both your cargo and the surrounding area.

You’ll need to carefully plan road routes to the port, avoiding busy areas, peak hours, and clearance issues. It’s also vital that you account for bridge heights, road widths, weight limits, and other obstacles along the entire route. To do this, you need to create a detailed road survey to proactively identify and resolve any potential problems.

Consulting with both transit locations is also important before shipment, and there is some key information you need to provide:

- Handling capabilities or needs

- Site requirements

- Access requirements

- Cargo sensitivity

- Crane needs

You should provide a technical description of the load, thoroughly prepared with an engineer, detailing the OOG cargo’s dimensions and centre of gravity. This ensures the correct lifting equipment and lashing materials are sourced and used during transit. These plans also help loadmasters create loading plans for both ships and aircraft.

Safe and compliant transport of your goods also requires accurate load measurements and weight calculations. These should be provided in advance, along with your completed permits and risk assessments.

In most cases, cargo handovers to terminal operators are simple and straightforward, but they do require prior coordination. For example, crane lifts will need accurate diagrams, vetted suppliers, and minimised risk. Proper customs procedures are also essential for avoiding financial issues or delays to your shipment.

Transport equipment

Once your shipment has been carefully planned ahead of shipment, you must select the appropriate transport equipment. Trailers, forklifts, and cranes are commonly used in the transit of OOG cargo, so you’ll need to make sure this specialised equipment is ready and able to handle your cargo’s non-standard dimensions and weight.

Alongside the big pieces of equipment, you need to factor in the right security tools into your transport equipment plan. For example, lashing rings, straps, and chains are used to secure cargo during transit. As well as meeting the needs of your cargo, all the equipment you choose should comply with regulations, procedures, and processes.

Securing your load

When shipping heavy or irregularly shaped items, securing and lashing your cargo becomes even more critical. This involves using a variety of tools and techniques to make sure your load is stable and completely immobile during transit. While this protects your cargo, it also prevents shifting or falling items, enhancing road safety.

The most common methods of securing OOG cargo include:

- Straps

- Chains

- Ropes

- Lashing equipment

Want to learn more about how container lashing works?

From straps to chains, our guide explains everything you need to know to secure your load safely and ensure it stays in place throughout the journey.

Check out our full container lashing guide for tips, tools and real-world advice.

Read guideBy utilising these methods, you can create a network of restraints that evenly distribute the weight of the load. Before you get started with securing your cargo, you need to consider its weight, shape, and centre of gravity to choose the right equipment.

Regular checks during transit are also critical for maintaining the integrity of the lashing system. You should aim to stop regularly on the road, checking everything is safe and secure.

Like any transportation of cargo, this step doesn’t just guarantee the safety of your goods, but it also reduces the risk of accidents along the way.

Out of gauge cargo challenges

The shipping industry is not without its challenges, but shipping OOG cargo comes with a few extra hurdles to navigate. Due to its non-standard dimensions, specialist handling needs, additional equipment, and route planning, you’re likely to come across several hurdles.

These challenges typically arise from the need for careful risk management, regulatory compliance, and the potential for increased costs.

Route planning

The routes chosen for OOG cargo need to safely accommodate its weight and size, which may require fewer standard routes. For example, trucks may be forced to navigate around low bridges, narrow country roads, and other obstacles. This requires careful route surveys and advance notice of road closures, which can all take time to put together.

Regulatory compliance

National and local regulations must be adhered to when shipping OOG cargo, as well as obtaining relevant permits. This can vary significantly by region, increasing the time and cost of your shipment. For example:

- UK road freight and OOG cargo shipments require notification to the police and highway authorities, as well as region-specific permits.

- Internationally, there are different rules regarding permits, fees, and required documentation across each transit country.

Whichever route is chosen, compliance with permit regulations and other processes is essential, particularly at borders or in areas with road restrictions in place.

Specialised equipment

As we’ve mentioned, handling OOG cargo means specialist equipment such as heavy-duty trailers, forklifts, cranes, and securing mechanisms are required. It’s possible that some of this equipment may not be readily available when you need it, which can add to the overall cost and complexity of your shipment.

Need the right equipment to secure your container?

We offer a wide selection of container lashing gear, including D-rings, twist locks, and stacking pins – all suitable for transport, storage and on-site use.

Explore our range of lashing equipment built for safe, secure container shipping and storage.

Buy Container Lashing EquipmentSafety concerns

While all cargo comes with safety concerns, OOG cargo presents some unique safety risks during loading, unloading, and transit. The size, weight, and potential for instability all add to the challenges around safety. This is why proper securing and handling are vital for preventing damage and accidents.

Cost implications

It’s typically more expensive to ship OOG cargo due to its size, increased insurance costs, and the need for specialist equipment, route modifications, and permits. Thorough planning can help to mitigate some of the costs, ensuring your budget factors in all confirmed and potential costs.

Handling risks

Human error is often unpreventable, but proper handling planning can help to ensure your cargo is safely moved, loaded, and secured throughout its journey, while also delivering safety for the workforce involved. You must make sure you have pre-planned for every eventuality and completed all the right paperwork ahead of time.

Insurance coverage

With the increased risks associated with transporting OOG cargo, you may need to purchase specialist insurance coverage. This is often more expensive than traditional shipment insurance and may be harder to find.

Equipment availability

Availability of specialist equipment and transport methods is not always guaranteed, particularly in certain regions or during peak seasons. Before you commit to any form of transportation for your cargo, securing the availability of the right equipment is critical.

Documentation

There is a lot of paperwork to complete when shipping out of gauge cargo, and it can be overwhelming. But it’s important to get it right to avoid increased costs or delays to your shipment. You should gather accurate and detailed information about your OOG cargo, including dimensions, weight, securing methods, and required diagrams.

Port congestion

Ports receive and handle large shipment deliveries and experience busy periods, but OOG cargo often requires additional space for correct handling and storage. Without the right planning in place, you may face delays at ports, resulting in increased costs and lost time.

OOG cargo innovation

Like many industries, the shipping industry is experiencing a boom in innovation. For out of gauge cargo, this focuses primarily on enhancing safety, efficiency, and visibility throughout the transportation process.

The advance of Industry 4.0 is putting key technologies such as real-time tracking and monitoring, IoT, automated route planning, and simulation software at the forefront. Logistics companies are increasingly investing in specialist equipment to improve innovation in the industry, from semi-automatic spreaders and modular spreader frames to digital twins and advanced software. All of this technology supports risk reduction alongside safety and efficiency optimisation.

However, innovation does not come without risks and additional considerations. Cost is a big factor, with many technologies requiring a significant investment up front before the return on investment is realised. Additionally, there could be problems with system compatibility, data integration complexities, and specialist insurance.

Cybersecurity is a huge consideration, too. You need to make sure data privacy is maintained in an increasingly interconnected environment. This requires specialist knowledge, which can also be costly.

Overcoming the technical challenges that come with innovation requires a strategic approach. But with planning, continuous learning, and collaboration with experts, you can navigate the complex landscape of modern technology implementation.

How much does it cost to ship OOG cargo?

It can be expensive to ship OOG cargo, largely due to the additional costs involved, such as permits, planning, and specialist equipment. It also takes up extra room on a vessel, reducing the space available for other cargo. This wasted capacity, often referred to as ‘lost slots’, is typically charged as an additional fee by shipping companies.

Depending on your load and the method of transport selected, you may also need to consider costs for road transit escorts. Sea transport may also need flat rack or open-top containers, which can also increase costs.

Finally, delays, route changes, and potential storage fees due to weather or infrastructure can also contribute to your costs. Accurately budgeting your OOG cargo shipment is critical, but working with experienced partners can support this.

The bottom line

Transporting OOG cargo demands careful planning, specialist equipment, and a little bit of know-how, but it’s not impossible. Although it can be complex and costly, many people ship OOG cargo all around the world every day. The key is understanding all aspects involved and planning your shipment processes to a tee.

Need help understanding more about OOG cargo or transporting your own shipment? Our friendly team is on hand to support you with any enquiries you have.

Looking for a completely custom solution?

We have a wide range of base containers that can be customised to your needs, however we

realise

that

sometimes you need something completely ‘Outside the box’.

Contact us and one of our experts will be in touch to help design the container of your

dreams