Every day, thousands of container ships criss-cross the oceans, each one carrying hundreds of shipping containers. Even more containers sit in shipping yards, on railways, and on trucks. Some of them are even used as homes, offices, storage spaces, and workshops.

Shipping containers are built for stability and security, no matter where they’re placed. Once locked together, they stay firmly in position, preventing shifting or imbalance.

With various locking methods available, choosing the right one is key to keeping your container safe and secure. The right system ensures your containers stay in place, giving you peace of mind and long-term reliability.

Why do shipping containers need to lock together?

In transit, shipping containers are locked together for two main reasons: security and stability. However, locking mechanisms are important for converted shipping containers, too.

Securing the contents

Locked shipping containers are extremely secure. They’re designed to protect cargo from theft or damage. Because of their convenient rectangular shape, it’s also easy to organise and track each shipment: for example, three containers with the same cargo might be stacked and locked together for easy reference.

Ensuring stability

When containers are locked together, they’re more stable. There’s less risk that a stacked shipping container might slide off, or that containers side-by-side might shift around. Locking containers also helps to maximise the space available on a carrier ship or truck.

Container conversion safety

Once a container comes off a ship and onto your land, the locking mechanisms are still important. Shipping container locks keep you and your possessions safe.

Containers for storage, site offices, or tiny homes are often placed in remote locations where security is paramount. As well as reducing the risk of theft, the locks prevent anyone from damaging the container’s structure through forced entry.

How do you keep a shipping container secure?

There are plenty of ways to protect your container, from heavy-duty padlocks and lockboxes to advanced security systems. Choosing the right method ensures your container stays safe, secure, and tamper-proof.

Learn the top security solutions to prevent theft, tampering, and unauthorised access in our detailed guide.

Read guideWhat is a shipping container lock?

Shipping container locks aren’t like standard door locks. They’re made of strong materials—usually steel—with a special design that resists weather, movement, theft, and tampering.

The most common type of shipping container lock are crossbar locks. Some containers also have extra security features, such as additional container padlocks, lock boxes, door alarms, and GPS tracking systems.

However, when discussing shipping container locks in terms of locking containers together, we’re referring to twist locks or stacking pins. These aren’t traditional security locks but rather mechanisms designed to securely connect containers.

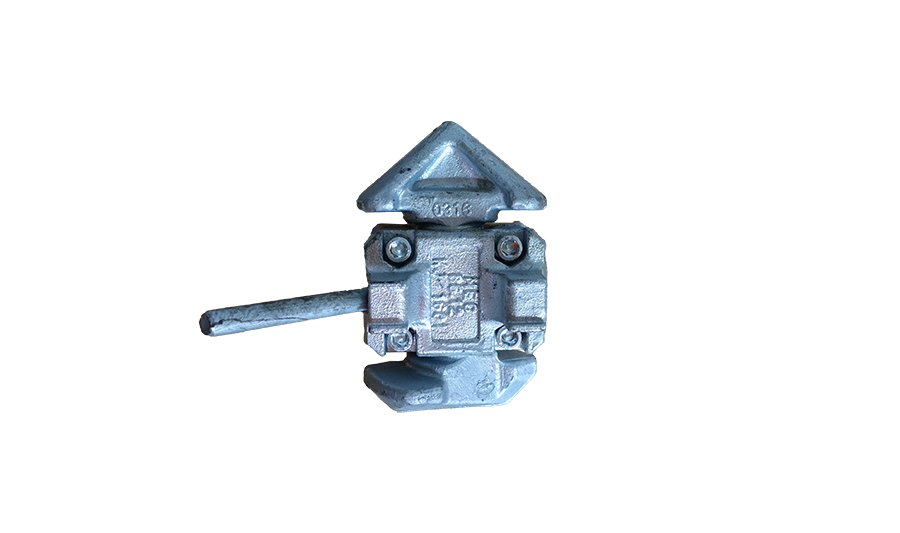

How shipping container twist locks work

Twist locks work with corner castings – the three-holed corners that you’ll notice on your shipping container. You’ll need four twist locks: one for the top left, top right, bottom left, and bottom right corner.

Here’s how it works:

- Put the twist lock through the hole of the lower casting.

- Put the other end through the upper casting (or, if you’re joining containers together, through a casting on the other container).

- Turn the lever to neutral to make sure everything’s in position.

- Turn the lever to the right to lock.

- Repeat until locks are installed on all four corners.

- Use the operating rods to control the locking system around the whole container.

Types of shipping container twist locks

There are several different types of twist lock, each designed for a specific situation. The two main categories are vertical and horizontal twist locks.

Vertical twist locks

Vertical twist locks come in three different types.

First, there are manual twist locks to use on a vehicle chassis. These hold containers securely before they’re driven around. Similarly, dovetail twist locks help to secure containers on any flat surface.

And finally, double-ended twist locks are used when you want to stack multiple containers on top of each other. They can be manual, semi-automatic, or fully automatic.

Stacked shipping container twist locks

With manual twist locks, you insert the lock and move the lever yourself. Semi-automatic and automatic locks are designed to save you some time and effort.

Semi-automatic twist locks are spring-loaded. Instead of turning a lever after fitting the lock together, you pull the spring into neutral position and then insert the lock into the corner post to trigger it. With an automatic lock, you don’t even have to adjust the spring: as soon as the containers are stacked, the lock snaps into place.

Horizontal twist locks

Horizontal twist locks are exactly what they sound like: they connect containers side-by-side. They’re used to secure containers during transport, or to help connect containers in a building conversion.

In addition to horizontal twist locks, you can also get bridge clamps which stop containers from tipping or falling. They’re very heavy duty, with extra turn buckle bolts, and can be useful if you’re building a large or complex structure.

How to choose a shipping container twist lock

The range of different locks might seem confusing. To choose the one you need, think about how your container will be transported, where it will be placed, and whether it needs to connect to other containers.

Container transportation

First, consider how the container will get from the supplier all the way to your property. It might need to be secured on a truck with a chassis lock, then locked onto a base once it arrives. Most container suppliers offer a delivery service, so they may take care of this stage for you.

Castings and foundations

You can place a container on different types of foundations such as flat ground, a poured concrete base, wooden beams, or a base plate. If you use plates or have multiple containers, then it’s a good idea to use twist locks to hold the container in place.

Container lifting

When you’re installing multiple containers, you’ll need to think about installation equipment as well as twist locks.

You can use a container lifting jack for just one or two containers, but you’ll need a forklift, crane, or swing lift if you plan to stack containers. If you want to install containers side-by-side, you’ll need plenty of clearance so that you can move them around easily.

Twist lock installation

Installing the lock itself should be fast and easy. Once the locks are set up on all four corners of the container, you can use the operating rods to lock and unlock it in place when needed.

How to install a twist lock on a shipping container

Properly installed twist locks are extremely reliable and secure. Follow these steps to make sure that yours are at their best.

Choose twist locks with ground plates

Twist locks with ground plates make a solid foundation for your container conversion. They stabilise the container on the ground, so it won’t shift around over time, even with a heavy load on top.

Ensure the shipping container locks in the same direction

When you install and activate the locks, make sure they’re all facing the same direction. It might seem like a small detail—but it makes it significantly harder for thieves to pick or break the locks. Plus, it’s easier for you to check the locks with a quick glance.

Check the shipping container twist lock features

Make sure that you’ve chosen the right twist lock for the job. Whether you’re stacking shipping containers, linking them, or just want to secure a single container, you’ll need a specific type of twist lock.

Inspect the twist locks before use

Check that the locks are in good condition before you install them. Any cracks, rust, or debris could weaken the lock over time. The locking mechanism should move smoothly, and all the locks on the container should be aligned in the same direction.

Looking for the perfect shipping container for storing goods or a conversion project?

Check out our full range of new and used shipping containers to find the right fit!

Shop containersOther types of shipping container locks

Twist locks are the most common locks used on shipping containers, but they’re not the only type you can use. Other devices can increase the security and stability of your container conversion, too.

Corner castings

Corner castings add extra reinforcement, support, and security to your shipping container. They help it retain its shape, even under pressure or rough transportation.

If your container doesn’t already have them, you can get additional corner castings to stabilise it.

Bridge fittings

Bridge fittings, or bridge clamps, are a durable way to link containers together. They’re specially designed to hold up under heavy weights, and you can get them in a range of size and materials for different conversion projects.

Gaskets

Gaskets are small pieces of rubber or silicone that are fitted around container doors to make an airtight seal. They protect the container’s contents, as well as the container itself, by keeping moisture and contaminants out. They also add insulation to keep the temperature inside the container at a consistent level.

Padlocks

For an extra layer of security, you can secure the locking bars on your shipping container with padlocks. Container padlocks are made of hardened steel that can hold up in harsh weather conditions—and even under physical attack.

The most secure padlocks are disc padlocks. Their round shape makes them difficult to attack with bolt cutters, and they fit securely around the locking bars.

Lock boxes

You can add even more security on top of padlocking the container. Lock boxes are metal containers which are welded onto the container, shielding the padlock.

Cross-bar locks

Cross-bar locks are another way to add security to the door of your shipping container. Each lock is a metal bar that extends across the width of the door, secured with another high-strength lock.

Internal locks

If you plan to live or work inside a converted container, then you’ll want to install internal locks as well. Deadbolts and slide-locks are both effective ways to secure your container from the inside.

Cam locks and handle locks

You can install a cam lock as a back-up in case any of your other security measures fail. A cam lock prevents the door from being opened even if the main lock is unpicked or damaged.

Alternatively, you can install a handle lock, which locks the door handle in place so that it can’t be turned or moved.

Seal Locks

Seal locks are useful if you want a way to check for tampering. Bolt seals can be placed through the container’s locking bars, while cable seals can be threaded through any locking mechanism. Both types of seal will strengthen the lock—and make any damage immediately visible from the outside.

Electronic and smart locks

The latest technology in container security is electronic locks. You don’t need a key to use these locks. Instead, they can be controlled with passcodes or access cards. You can even install smart locks which are controlled remotely through Wi-Fi or Bluetooth.

The main benefit of these locks is that they monitor the container in real time. Some smart locks will record entry times, update pass codes, and even alert you if someone unauthorised tries to open the container.

The bottom line

There are lots of different ways to lock shipping containers together. Mechanisms like twist locks help you to transport and place containers securely. You can also use other types of lock to protect the contents of your container. However, it’s important to choose the right lock for your container, and maintain it in good condition.

FAQs

How high can shipping containers be stacked?

Containers can be stacked up to 9 high on a cargo ship. In a storage yard, the stack could go even higher! In practical terms, the height of the stack is limited by safety concerns and weight limits. Stacked containers should always be locked in place and secured at the base for safety.

Can I bolt my shipping container to the ground?

You can bolt your shipping container to the ground to make it more secure and stable, especially if you plan to stack containers or use the container as a living space. It’s a good idea to consult a professional who can help you choose the right method to secure the container.

Can I move my shipping container on wheels?

Wheeled trucks are a great option for transporting containers on land. You’ll need chassis locks to hold the container in place during transit. You’ll also need to think about weight distribution, so that the container isn’t prone to sliding off the truck or throwing it off balance. It’s usually best to hire a specialist company that knows how to transport containers safely.

Looking for a completely custom solution?

We have a wide range of base containers that can be customised to your needs, however we

realise

that

sometimes you need something completely ‘Outside the box’.

Contact us and one of our experts will be in touch to help design the container of your

dreams